Conventional soldering stations normally use a feedback circuit mechanism to control the soldering iron tip temperature, whereas a ‘curie point’ temperature controlled soldering iron relies on the natural properties of the soldering iron material to maintain a constant controlled temperature level.

The basic property that allows curie point temperature control to work is; when heated materials lose their magnetic properties, the temperature at which this happens is called the ‘curie temperature’. The curie temperature differs for different material, for example Iron has a curie temperature of 770℃, whereas Nickel has a curie temperature of 358℃.

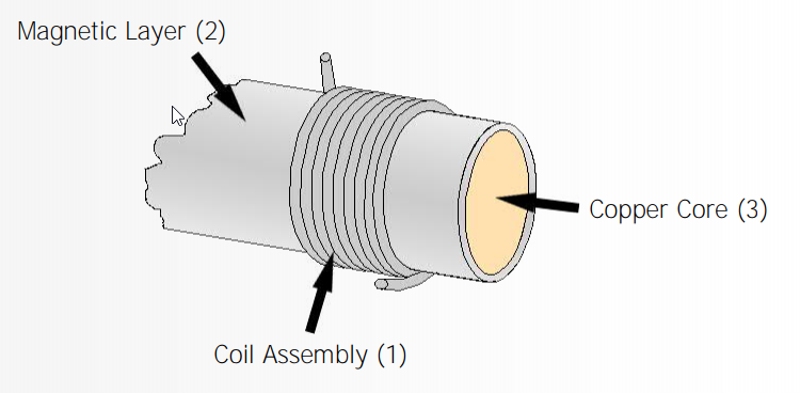

Now that we have established the fundamental principal, let's take a look at how a curie point soldering iron works. Figure 1 below shows a cross section of a typical curie point soldering tip. The outer surface (2) of the soldering tip is an alloy with magnetic properties, the inner core (3) is a highly conductive material, like copper, a coil (1) is wound around the tip to create the inductive heating.

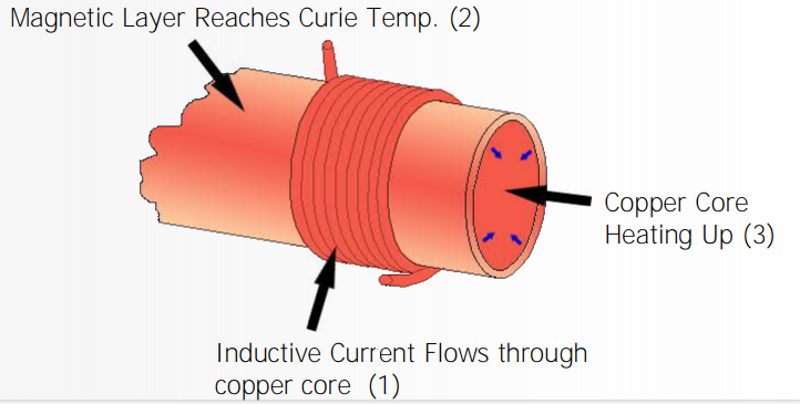

As shown in Figure 2 below, when a high frequency current is passed over the heater through the coil assembly (1), the tip temperature increases due to a phenomenon known as the ‘skin effect’, the inductive current flow is confined to the “skin” or magnetic layer (2) of the heater. This causes the heater to heat up rapidly.

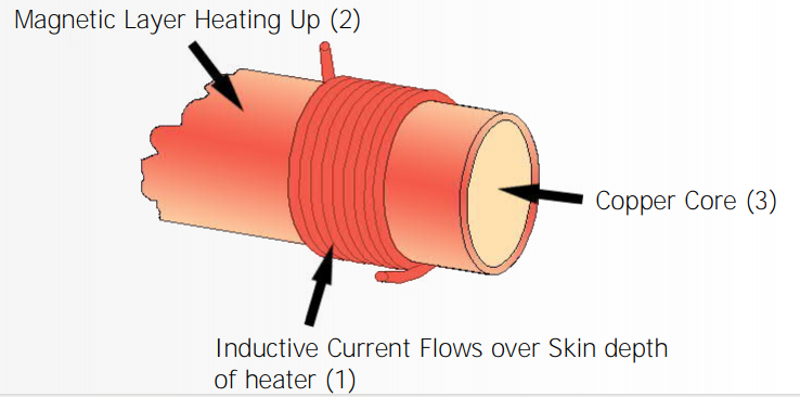

This process continues until the curie temperature is reached, at the curie point the alloy loses its magnetic properties, hence the inductive current skin effect (2) ceases, and causes the transfer of inductive current to the copper core of the heater (3). The tip temperature ceases to rise and the tip temperature will eventually slightly drop, as shown in Figure 3 below.

When the tip temperature falls below the curie point, the alloy regains its magnetic properties, and inductive current will once again flow through the alloy and raise the tip temperature. This cycle continues to repeat rapidly, hence maintaining a constant tip temperature.

Because curie point inductive heating does not rely on external control circuits to maintain the soldering iron tip temperature, they are less susceptible to temperature overshoot, and will provide a reliable, and well regulated temperature level at all times.

| 55W 470kHz ESD Safe Soldering Station Thermaltronics TMT-2000S-K soldering station Rapid response 470kHz Curie heating technology Includes K-series 0.5mm conical tip View Online |