3D Printing

Discover the limitless possibilities of 3D printing with our industry-leading range of 3D printer products and learning resources. Find everything you need in our new video series, or shop for all the best printers and supplies online and in-store at Jaycar.

What is 3D Printing?

3D printing is changing the way we produce things. Instead of buying a physical item from a store or having a professional manufacturer make a prototype of your idea, you can now print it in your home, office, workshop, etc. There's no tooling necessary which opens up a world of opportunity to the designer - or everyday Joe just wanting to make cool stuff. There's also an element of self-sufficiency and novelty: the notion that you not only sourced an item locally, but made it yourself! If you're not a designer, there's a number of 3D printing libraries online where you can download free CAD drawings which you can print, and at the same time interact with other fans on tips and processes. 3D printing is a fun, exciting and quickly evolving world.

How Does 3D Printing Work?

3D printing is an "additive production process". That means that it prints a 3D item in hundreds (or even thousands) of super-thin horizontal layers from the bottom up to form a solid object. Due to this layering process, the printer can create hollow objects, intricate internal components, and moving parts like hinges and wheels inside a solid case - which you cannot achieve with traditional manufacturing. The objects you're planning on 3D printing will determine what quality and capabilities you need your 3D printer to have.

Explore 3D Printing Supplies at Jaycar

Jaycar stocks 3D printing supplies suitable for every need. Whether you are after filament, accessories or a 3D printer itself, we have you covered!

3D Printing FAQs

Read our frequently asked questions about 3D printing to learn everything you need to know.

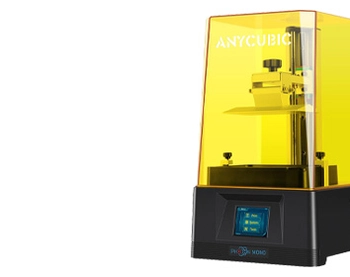

Filament (FDM) 3D printers and resin 3D printers are the two most common types of 3D printers on the market. FDM printers like our Ender-3 S1 Plus from Creality offer a larger build area of up to 300x300x300mm, plus a wide range of features making them easy to use and maintain. They are easy to set up and customize to fit your workflow or hobbies, making them a versatile option for props, rapid prototyping, and everyday models. However, FDM printers lay down each bit of material one by one, which means they can be slower than resin printers.

Resin printers, on the other hand, typically have a smaller build size and are limited to a single resin during the print process. However, they offer significantly higher quality and precision than FDM printers, making them ideal for creating small, highly detailed models and parts such as DnD or Warhammer models, and small high-detailed prototypes. Resin printers can print an entire layer of the model in one go, resulting in faster printing at higher detail. However, resin printers require more post-processing steps, including cleaning up the resin, washing and curing the prints, and handling the resin fumes which can be harmful if not properly ventilated.

Ultimately, the choice between filament and resin printers depends on your project needs and personal preference. Filament printers are versatile and easier to use, while resin printers offer superior quality and precision at the cost of more post-processing work and the need for proper ventilation to ensure safety.

Learn More About 3D Printing

Want to know more about the world of 3D printing? Our articles have you covered!

New 3D Printing Video Series

More Videos

More Videos

Showing 1-4 of 5 videos